Impression 3D

Notre département

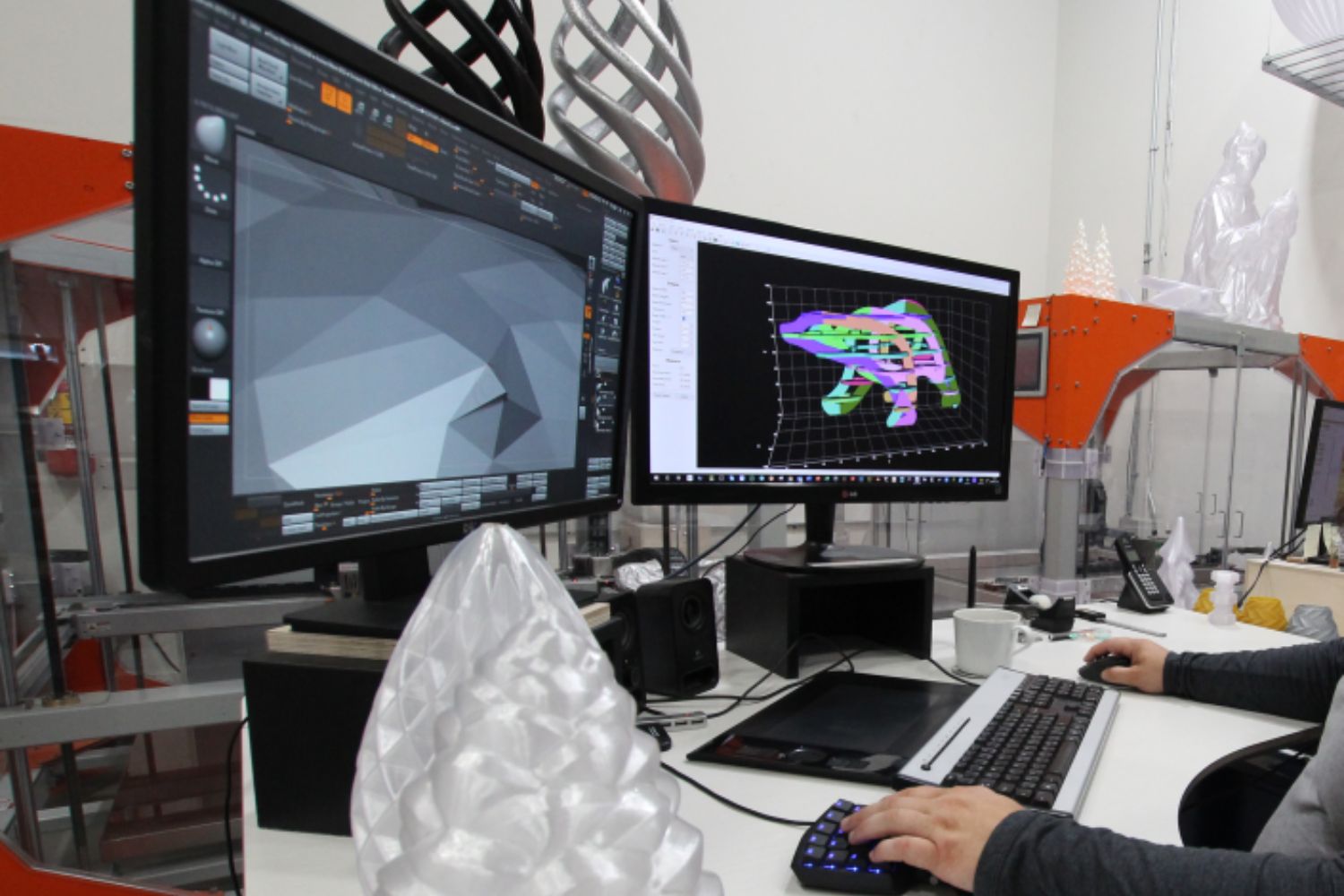

Adopter l’impression 3D non seulement comme outil de développement et de prototypage, mais aussi comme réel moyen de production est une des façons dont nous changeons les règles du jeu. Nos imprimantes 3D grand format et l’expertise que nous avons développée au cours des années rendent ce département unique en son genre.

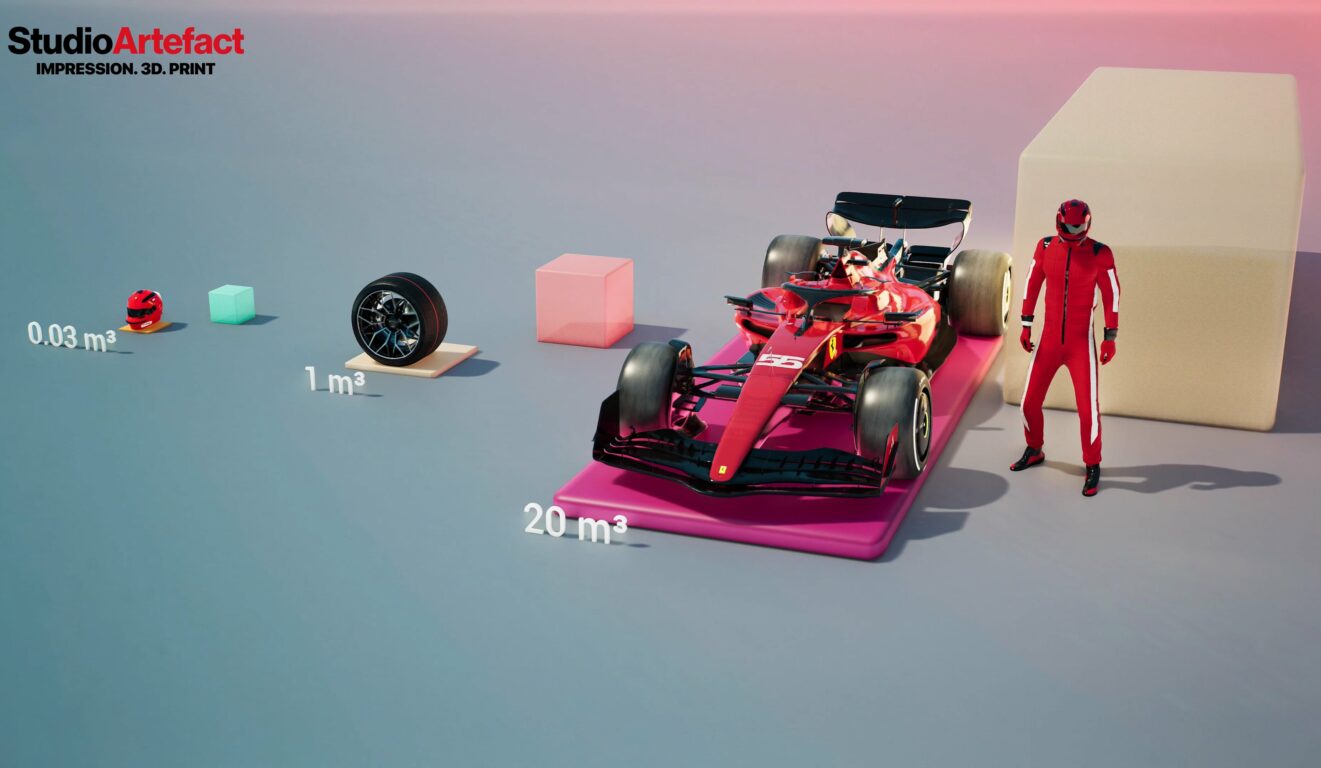

Ce qui nous différencie du reste de l’industrie, c’est l’aspect TRÈS grand format de nos imprimantes ainsi que notre capacité de production incomparable. Nous sommes fiers d’avoir fait la récente acquisition de la toute première imprimante 3D au Canada capable de réaliser des impressions de 20 m³. Cet ajout révolutionnaire à notre atelier marque un pas important dans notre engagement à repousser les limites de la créativité.

En plus de cette nouvelle machine, notre département est composé de 6 imprimantes grand format pouvant imprimer jusqu’à 1 m³. Elles fonctionnent selon la technique d’impression additive qui consiste à chauffer un filament de plastique qui est ensuite déposé en couches successives pour créer un volume.

Avantages

- 01 L’impression 3D est une option durable (matériel résistant à la chaleur, flexible, léger, hydrofuge…).

- 02 Nous vous proposons transparence et intégration lumineuse, grâce à l’utilisation de filaments PETG transparents, pour des résultats impressionnants. (Utiliser l’impression 3D en transparence nous permet de faire des choses qu’on ne pourrait pas faire autrement)

- 03 Repoussez les limites du possible à l’aide des formats d’impression 3D que permettent nos machines grand et très grand format.

- 04 Nous travaillons avec des matériaux recyclés et recyclables qui assurent une gestion écoresponsable de notre production.

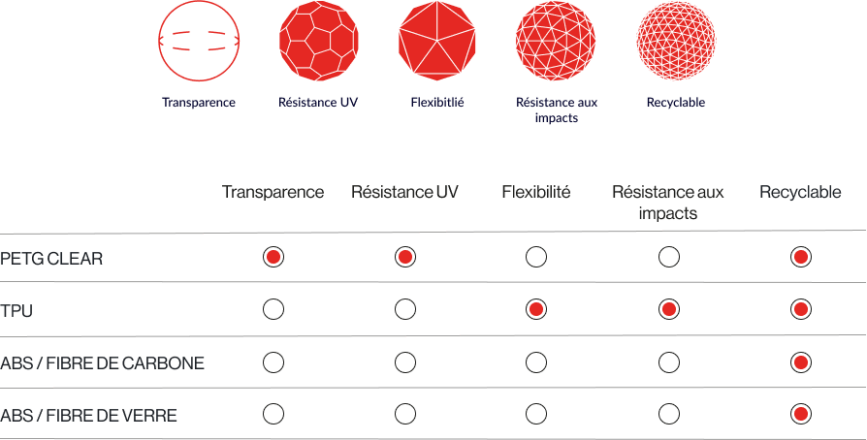

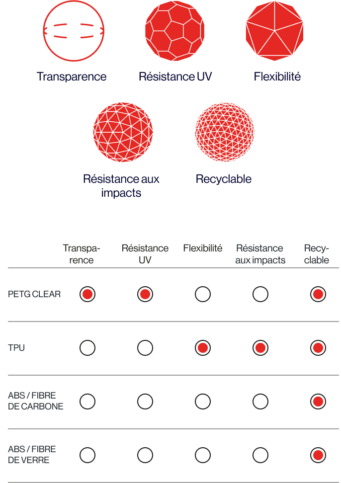

Matériaux et leurs caractéristiques

L’impression 3D est à la fois un outil technique de production et un vecteur de création. C’est une excellente alternative aux méthodes traditionnelles, tout en permettant de créer des formes complexes à un coût très raisonnable. Plusieurs caractéristiques font de l’impression 3D notre méthode de production par excellence.

Champs d’application dans les secteurs d’activité

Les nombreux avantages de l’impression 3D font de ce département un outil artistique incontournable à l’atelier. Nous réalisons des installations uniques pour une variété d’industries. En plus d’une grande capacité d’impression, nous vous offrons une expertise de pointe et un support au design qui vous permettra d’amener vos idées encore plus loin.

Respect de l’environnement

L’impression 3D est un procédé de production écoresponsable puisqu’il utilise exclusivement le matériel nécessaire pour l’impression, ne résultant presqu’aucune perte. Les retailles accumulées au département d’impression 3D du Studio Artefact sont distribuées dans des établissements scolaires, comme le Cégep du Vieux Montréal, afin de réaliser des projets étudiants et de pousser leurs apprentissages autour de cette impressionnante technologie. La majorité des matériaux utilisés pour l’impression 3D sont recyclables, et même dans certains cas biodégradables.

NOS RÉALISATIONS

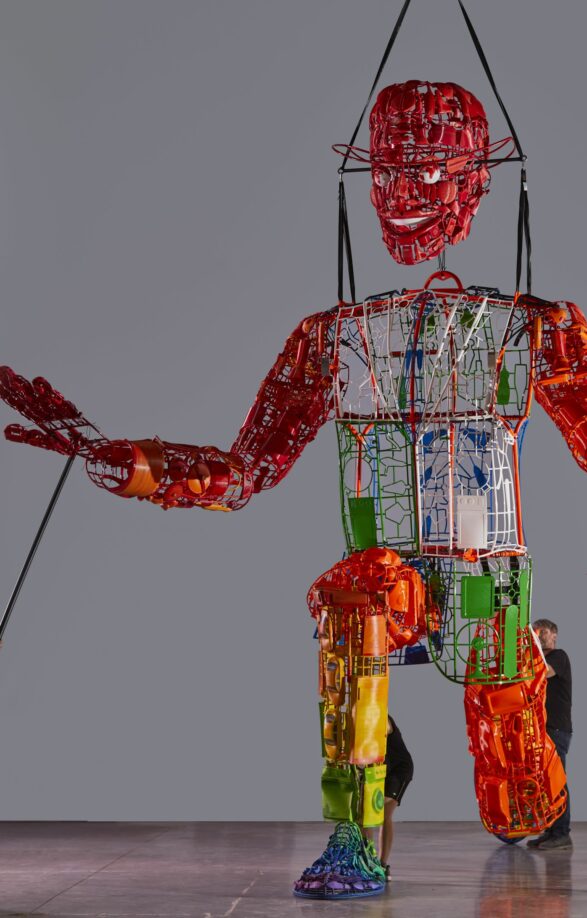

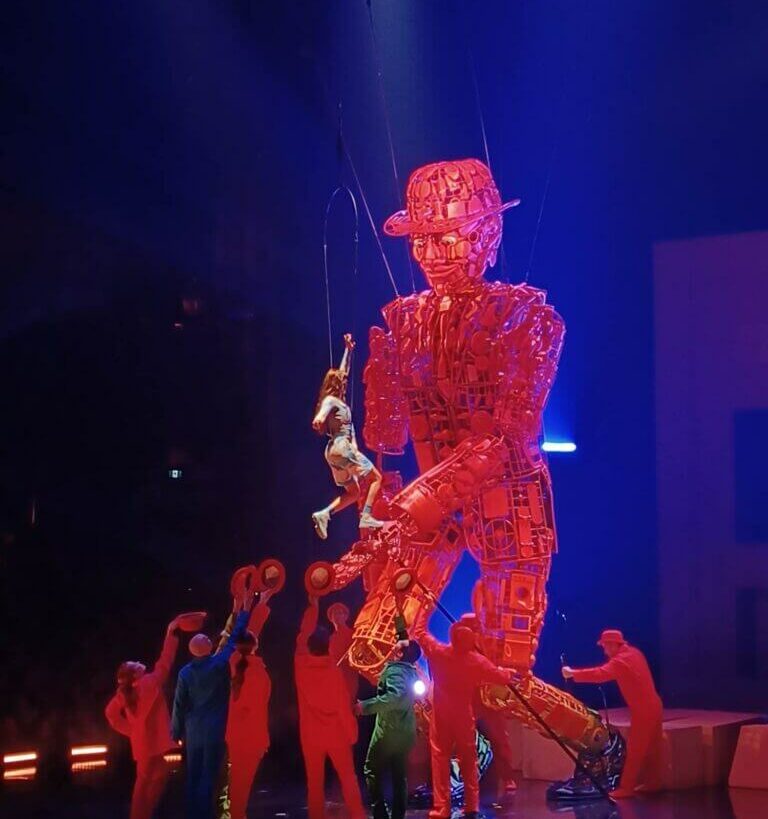

ECHO – Marionnette géante

- Spectacles - Scénographie

Mandat collaboratif pour la conception et la fabrication d’une marionnette haute de 24’ pour le Cirque du Soleil.

« WildWoods : AGLOW »

- Musées & Expositions

- Parcours immersifs

En collaboration avec Thinkwell Group, nous avons travaillé sur un projet de forêt illuminée multi-sensorielle et immersive pour le Ferbank Museum.

L’Expérience Immersive Donjons & Dragons

- Musées & Expositions

- Parcours immersifs

Studio Artefact est fier de présenter son savoir-faire inégalé dans la production de « Donjons et Dragons : La Quête Immersive », une expérience interactive réalisée par VIBRANT Studios.